Choosing A Generator For Use In Off-Grid Systems

Sometimes, if generation is less than consumption, the only way to keep an off-grid power system operating is by using an engine generator. However, many generators are poorly matched to the job, resulting in inefficient, unreliable performance. It’s important to choose the right unit for the job.

An investment in quality quickly pays off. The least-expensive ‘Portable Generators’ are designed for occasional use with power tools for instance, or to provide temporary power. A better alternative for off-grid systems are ‘Prime Power Generators’ which tend to have higher cost.

Function & Purpose

By including a genset you have insurance against losing power after extended periods of inclement weather, against excessive battery cycling which shortens the life of your expensive batteries and the flexibility to increase your load if required. Generators serve three main roles in off-grid systems:

- Backup charging. Where the generator makes up for any deficit in energy from the solar array or wind turbine, since the generator will work in any weather.

- Lead-acid battery equalising. Equalising is the deliberate overcharge of a battery—raising the battery voltage to a higher-than-normal voltage (as specified by the battery manufacturer) and keeping it there for 2 to 3 hours. This is usually done several times each year to ensure best service life and performance. A minimum charge rate of about C/20 is necessary to overcome internal resistance to achieve such a high voltage. Most off-grid PV arrays aren’t powerful enough to accomplish this, especially during the winter, so a generator becomes an essential tool.

- To run high loads. A generator will also let you power heavy loads that exceed the capacity of the inverter.

Features Needed

Automatic Generator Start:

In some cases, a diesel generator is present only to boost battery voltage after a lengthy period of inclement weather. In these cases, a manual on-off switch may suffice to control when the generator is turned on. Automatic start generators are capable of remote start. This means that the start and stop signals can be sent by an external signal, such as from an inverter or other controller, as can other system components such as a manual switch, a voltage-controlled relay, a threshold signal in some system monitors, and even a signal triggered by a big load.

The control over the generator’s operation - that is, when to run and when to stop is external to the generator, while the generator provides all starting control functions (such as cranking and crank duration), together with it's own safety protection, such as shutoff for low oil level, overheating, and other factors. Remote-start generators need to be fitted with a control panel featuring a 2-wire remote start facility in which a closed contact tells the generator to start and run. When the contacts open, the generator stops.

An inverter with generator-start capability can connect to this control panel to control the generator. When it detects a set low battery voltage level or State of Charge, the inverter sends the signal, the genset starts and once up to speed and voltage, the inverter accepts power from the genset. (Start-up time should be considered to allow buffer time for the generator to start operating before the batteries are fully depleted and the system shuts down). Once battery is charged, the signal is removed and generator stops.

To optimise genset running time and to look after the system’s expensive battery bank, it is recommended that if the system is designed to be controlled automatically, it is left to work automatically.

Slow Running Engine:

To generate a stable 50 Hz or 60 Hz output, the engine powering the generator must rotate at a fixed and stable frequency. For 50 Hz output this is 3000 rpm or 1500 rpm, (For 60Hz 3600 rpm or 1800 rpm for 60Hz) depending on the number of poles of the generator High speed ‘2-pole’ gensets run at 3000rpm, and low speed ‘4-pole’ gensets run at 1500rpm. (3000 rpm / 60 seconds = 50 rotations per second = 50 Hz).

In general, generators designed for intensive use run at lower speeds.

High speed gensets are designed for intermittent light duty (< 300 hours/year) use and are not made to operate at full load for long periods of time. These cover practically all petrol powered gensets and a range of small air-cooled diesel sets. This type of genset is ideal for a very robust off grid solar system, where only extended periods of inclement weather should make its services necessary. It should be thought of as a diesel powered battery charger only.

Low speed gensets are designed for prime power use. They are able to both charge your batteries and carry the house load simultaneously, so offer both insurance and flexibility for your system. They are generally diesel powered, quieter and more durable than the higher speed gensets, but the initial capital outlay will be higher. They will also operate more quietly, with less vibration and lower fuel usage.

No or minimal standby load:

Some generators, designed primarily for on-grid standby use, draw energy - even when not running - for control functions, charging the starter battery, and even for pre-heating in cold climates. This can be acceptable for use with grid power, but not for off grid systems. A generator is required that has no parasitic draw when off, or a separate small PV module and charge controller can be added to keep the starter battery charged.

Starter battery charging when the engine is running:

Generators designed for on-grid “residential standby” operation sometimes require an external battery charger.

Liquid cooling, rather than air cooling:

Liquid-cooled machines will run quieter and, being thermostatically controlled, will run at a more even temperature year-round, resulting in longer life.

Floating or unbonded neutral-to-chassis connection:

Quality generators allow the neutral conductor to either connect to the generator chassis (for prime power application) or remain separate from it. Portable generators are seldom properly grounded, so manufacturers ground the neutral output conductor to the chassis. When connected into a grounded power system, however, this presents a safety hazard, as the neutral is now bonded to the ground at two places - one in the power system AC (such as in the main AC service panel) and one in the generator - and the safety ground wire becomes current-carrying. Some units also include AC ground-fault protection, which is incompatible with connection to a grounded power system.

Good local after-sale support:

Even in a well-designed off-grid power system, the generator is likely to be the single greatest source of maintenance and aggravation. Its a mechanical device, rather than electrical, so it requires regular maintenance and will eventually break down - usually when its most needed. The more serious the consequences of the inevitable breakdown, the greater the appeal of a top-quality commercial/industrial generator. Consider also that unless you are prepared to maintain and repair the machine yourself, you will need reliable local support when the eventual failure occurs.

Fuel Type

This could be petrol, propane, diesel, or biodiesel.

Petrol, used in the least expensive generators and nearly all portable units, offers some advantages -mainly that petrol is familiar and manageable by the unskilled user. However, its highly flammable, and fuel storage will need to be a consideration. Petrol gensets can struggle with remote starting as operating the engine's choke requires an additional mechanical operation. There is an automatic choke option available but this is often problematic, particularly in colder climates. Petrol engines also produce poisonous carbon monoxide gas so must never be run in a confined space. A petrol generator is best suited to applications where use is occasional. Most auto-start generators use other fuels.

LPG (propane) is commonly used in higher-quality stationary generators. Many off-grid homes already have an LPG tank for cooking or heating, so the fuel is convenient and relatively safe. Propane has an almost unlimited storage lifespan. LPG generators will generally start reliably down to about -10°C. Natural gas and propane burn cleaner than petrol and diesel, and wear on internal engine parts is reduced.

Diesel generators are typically long-lived and high-quality, though more costly. However, the fuel is best suited to warmer climates, as it can gel at temperatures below freezing. The drawback to diesel is that, compared to propane, it’s a “dirtier” fuel, producing more pollution and storage requires extra care against spills and leaks. Diesel generators can also be run on biodiesel or either virgin or waste vegetable oil, taking the appeal of “living on renewable energy” to a greater level.

Sizing a Generator

An off-grid renewable energy system should be designed so that in the event that the renewables and battery inverters are not able to meet the system demand, a back-up generator is able to meet the entire site demand and can supply the inverter's full charging capacity plus additional loads needed during charging.

To size, start with the size of the inverter charger you are using and work forward from there.

- If using a 2-pole genset you simply need to know how much power your inverter charger draws to charge your batteries, as this is all it should be used for.

- If using a 4-pole genset you have the flexibility to add the power the inverter charger needs for battery charging to the expected house load.

Generator optimum loading As a rule, most generators run best close to, but not at, maximum output. 85% of nameplate rating is a commonly used figure. This is the optimum loading which means it is operating at its most efficient point and avoids being overloaded when being run for long periods. They should also be sized so that under expected loads they are providing at least 40 % of their capacity, unless a manufacturer’s recommendation says otherwise.

Sizing As an approximate rule of thumb, the generator should be around 2 times the size of the inverter/charger’s continuous output. For example, a 4,000-watt inverter/charger should be paired with an 8,000-watt generator. This is because the generator needs to charge batteries while still powering the loads (appliances using energy). If the loads total 4,000 watts, and the charger is 60 amps at 48 volts, that totals around 7kW of continuous power: 60A x 48V = 2,880 watts + 4,000 watts = 6,880 watts 8kW would make sense as a minimum generator size to power the loads and have enough power to charge the battery bank as well (whilst not running generator at more than 85% output rating).

Elevation & Temperature Effects. Power output of all generators is rated for use at sea level. As elevation above sea level increases, air becomes thinner, with less oxygen. The result is decreased performance. Engines can lose around 3% of their power for every 300m increase in altitude. This needs to be accounted for if the system will be installed at a high elevation. Also, as the ambient air temperature increases, the engine and alternator heat up, which decreases both efficiency and power output. Generator manufacturers will rate power output at a given temperature, a typical deration is 1.5% per 10°C above rated temperature.

Finally, make sure the voltage and frequency output of the generator matches the input of the inverter/charger!

Protecting Generators From Overload When the genset is activated it is providing power to the loads as well as to the batteries via the bi-directional inverter/charger. The system should be capable of limiting the amount of current being asked from the genset. The typical way of achieving this is to react to generator droop: if the system senses that the frequency from the genset is dropping because it is reaching maximum load, then it will lower the amount of charging current being demanded for the batteries.

Reverse Power The system needs to protect the gensets against reverse power flow (power going back into the generator – causing it to motor in extreme cases) by limiting the power production of the renewable energy generators as required, or shutting the wind/solar generation off completely if needed.

See also:

Installing Generators

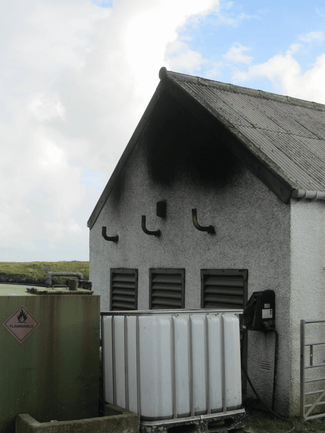

- Some gensets in enclosures can be installed outside, but like anything exposed to the elements they will weather faster.

- The genset must be installed on a level surface, preferably on a concrete plinth.

- The generator alternator is air cooled, drawing air though it along with contaminants in the air, so keep dust and dirt away from the generator. When moisture is added these will act as a grinding paste on the alternator windings eventually causing failure. Salt-laden air is worse.

- Cool, fresh, clean air is required for cooling and combustion and then need to get the warm used air away from the genset. The warm air cannot be allowed to recirculate. The exhaust outlet also needs to be designed in a way that exhaust fumes cannot recirculate through the genset.

- Do not install your genset in the battery room. Equally ensure equipment and flammable materials are kept well clear of the genset.

- Care must be taken to ensure all exhaust gases are ventilated away from areas that are inhabited by people or animals. If extending the exhaust pipe, do so in a manner that does not increase back pressure on the engine.

Generator Maintenance

- Read the operator manual supplied and follow the instructions.

- Make sure the starter battery is kept charged

- Run your genset regularly under load – at least once a month. If your inverter is setup to do this automatically, make sure the genset is actually starting and running as expected.

- Use the fuel in the tank. The diesel should be turned over a minimum of once a year – but more often in cold, damp conditions. Fuel goes off over time, which causes reliability issues.

- Keep it clean and dust free as already mentioned above.

- Change the oil and filters at the recommend operating hours or annually.

- Check hose clips annually.

- A good gauge of the genset’s health is exhaust smoke. All diesel engines will puff a little smoke when starting, however when running the smoke should be relatively clear, particularly when the set is up to operating temperature. White smoke suggests impurities in the fuel, normally water. Check the fuel filter for signs. Black smoke suggests it is overloaded or the engine is not getting enough air. Check the load and air cleaner. Excessive smoking indicates something is wrong that needs to be resolved.

Wind & Sun don't supply generators ourselves. Even in a well-designed off-grid power system, the generator is likely to be the single greatest source of maintenance so it is best to obtain this from a local specialist who can give good advice, install correctly and safely and then provide maintenance when required.

If you let us know where you are located we can usually recommend a suitable installer/supplier.