All cables must be suitably sized and rated for the maximum voltage and current calculated for the circuit in question, taking into account any relevant derating factors such as installation method or grouping.

If in doubt consult equipment installation manuals or an electrician.

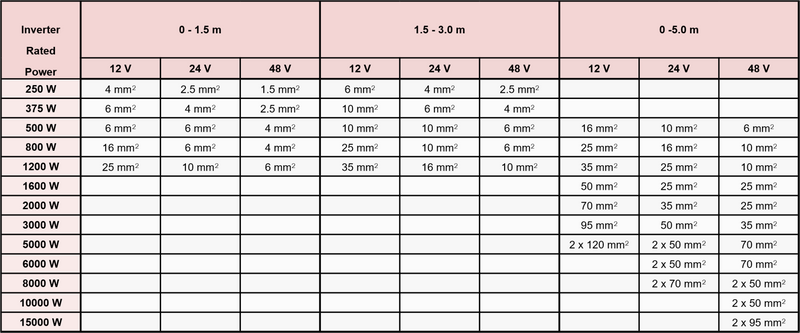

Battery and Inverter Cables

Very high currents can flow in cables connecting inverter to the batteries and between the batteries. Cables must be adequately sized to suit the maximum current drawn by the inverter. Low resistance links and tight connections are essential to maintain even use of a battery bank.

In order to minimise the voltage drop between battery and inverter, and so maintain inverter efficiency, cables should be kept as short as possible and be sufficiently sized. Please refer to equipment manuals.

Instead of using one very thick cable, smaller cables can be doubled up, using two cables per connection. The combined surface area of both cables must then be equal to the recommended surface area. For example, 2 x 35 sq. mm cables equal one 70 sq. mm cable.

Recommended Inverter Cable Sizes

Note: The sizes shown are given as a guide only. Please refer to equipment manuals for further guidance.

Products

Battery/Inverter Cables and Connectors

Very high currents can flow in cables connecting inverter to the batteries and between the batteries. Cables must...

View collection

Battery/Inverter Cable Assembly Tools

Used to ensure easy and correct assembly of cable lugs to battery/inverter cables

View collection