Wiring Solar PV Panels

Solar photovoltaic (PV) panels can be wired to increase voltage and/or current.

Caution: Dangerous voltages can be produced when panels are connected together

Some smaller panels are fitted with an output junction box with positive and negative terminals to facilitate wiring, however, the majority of panels come with a plug and socket connection.

Note: Plug and socket connectors mated together in a PV system should be of the same type from the same manufacturer. Different brands may only be interconnected where a test report has been provided confirming compatibility of the two types to the requirements of BS EN 50521.

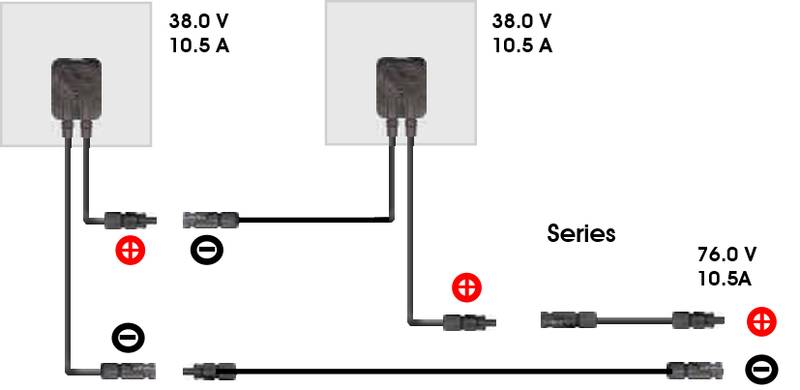

Wiring in Series

Connecting panels in series, in what is known as a series string, by wiring positive of one panel to the negative of the next increases the voltage to sum of individual panel voltages but keeps the current equal to that of the panel with the lowest current.

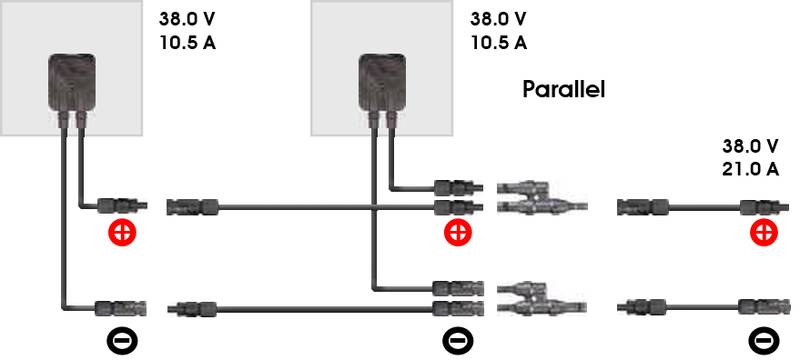

Wiring in Parallel

Connecting panels in parallel (wiring positive to positive and negative to negative) keeps voltage constant but increases current to the sum of the individual panel currents.

To increase both voltage and current panels are wired in series and then these series strings wired in parallel.

For some systems, the use of Y connectors (Branch Connectors) may be an appropriate means of connecting two string cables in parallel.

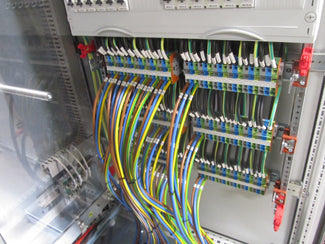

However, in systems with multiple strings connected in parallel some fault scenarios can result in the current from several adjacent strings flowing through a single string and the prospective fault current may be such that overcurrent protective devices are required. This can be be done by making the parallel connections in PV Combiner Boxes and using String Fuses. String fuses must be provided for all arrays formed of N parallel strings, where (N-1) x Isc (module short circuit current) is greater than the module maximum series fuse rating.

(Commonly this means string fuses are required when more than three strings are connected in parallel)

Solar PV Wire Management

This is sometimes not given enough attention but when done properly leads to longer lasting systems that require less maintenance over the lifetime of the PV system (20 to 30+ years).

Wire management is the practice of properly routing, organising, supporting, and protecting the wiring and is particularly important because of the harsh environments that PV systems are installed in.

- All wiring should be run in a manner that avoids damage to the cable insulation and conductor.

- Avoid sharp edges and rough surfaces

- Avoid overly tight bending radii.

- Protect from direct exposure to sunlight, potential damage by wildlife

- Cables should be grouped, routed and labeled in a manner that allows easy identification of different circuits for future maintenance.

- Avoid sagging wires by clipping or tying all cables securely and neatly at regular intervals. Use stainless steel wire clips, UV-stabilised cable ties, cable tray or supported conduit.

String Design

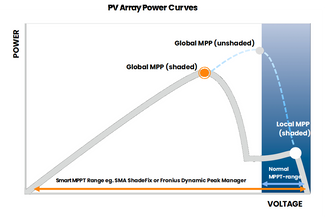

When planning wiring and string configuration of a PV array, the physical layout of the array must be considered in addition to electrical requirements of the inverter or charge controller being used. This needs to consider cable lengths and avoiding stringing cables across rows, gaps or thermal breaks together with possibility of any shading.

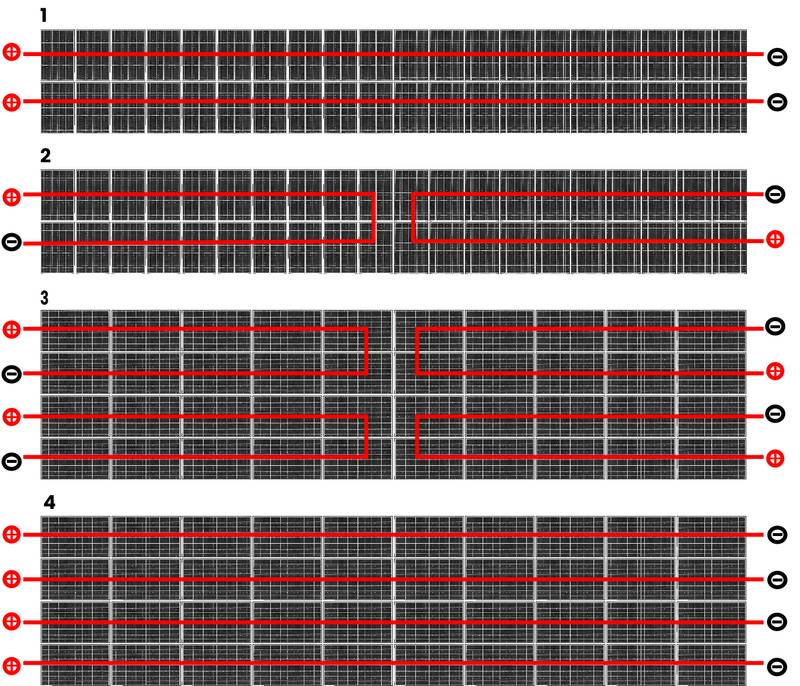

When the sun is low in the sky shade might only affect the lowest row of panels in an array, so to minimise shade losses strings should be formed from single module rows (as shown in 1 & 4 below). Grouping different rows on different MPPT inputs to inverters, or on different inverters can also improve performance.

Products

PV Combiner Boxes and String Fuses

These are used to allow the parallel connection of several strings of PV modules or to enable large...

View collection

Solar Cable and Connectors

Double insulated single core cable together with polarised weatherproof DC connectors.

View collection